Description

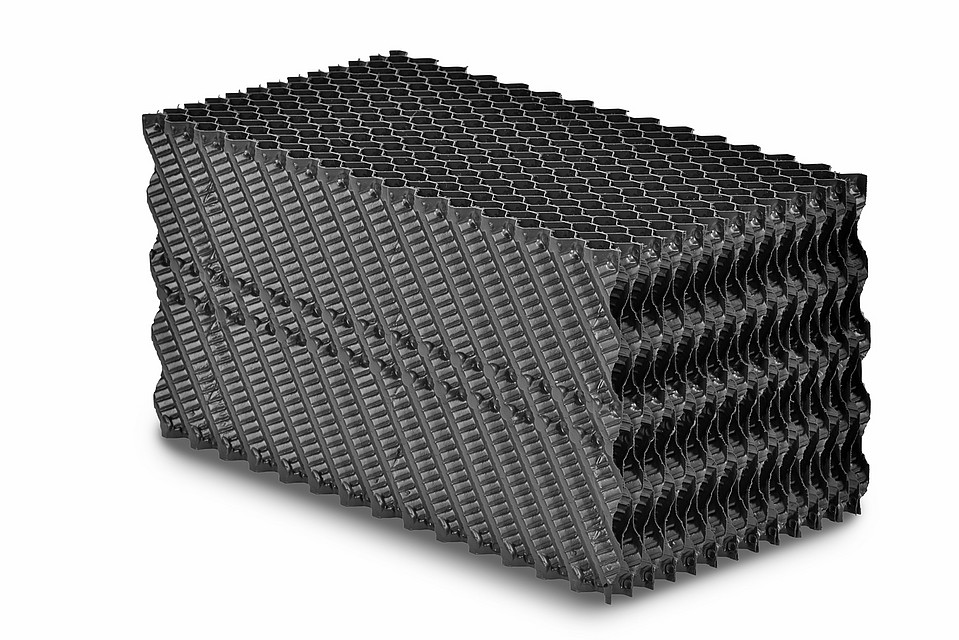

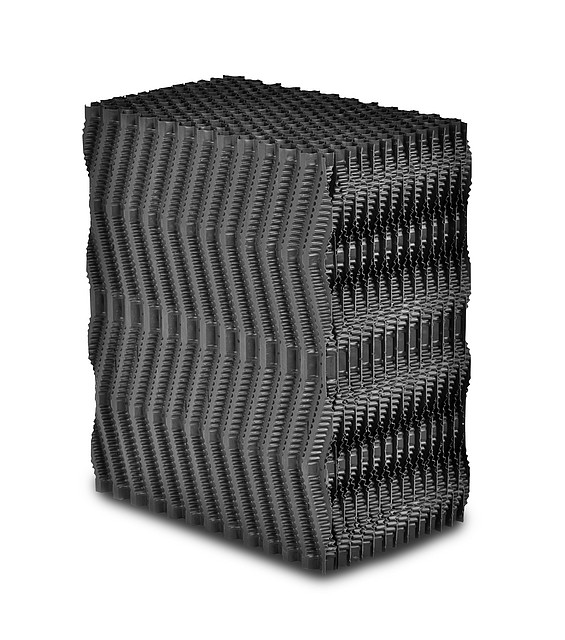

The CF-12 circular fill is a high-performance solution designed for efficient water and air distribution across a wide range of applications, including cooling towers, wastewater treatment, and agricultural systems.

Engineered for exceptional mechanical strength, its durability is ensured through a highly stable connection technology and a specially structured fill design, making it significantly more robust than outdated flat film constructions. The reinforced thick edges provide superior resistance to mechanical stress, ensuring long-term reliability in demanding environments.

Available in various strength classes up to 80 kg/m³, the CF-12 can be customized to meet specific operational requirements. It is made from solvent-free, environmentally friendly materials and processed using advanced welding technology, with up to 250 spot welds per unit for maximum stability.

Additionally, it meets all fire protection standards, ensuring safe and reliable performance. The CF-12 is available in two design variants:

- V: Single-direction air/water flow change, with an installation height of 600 mm.

- VV: Triple-direction air/water flow change, also with an installation height of 600 mm.

Our specialized welding machines allow for customized production, suitable for both permanent installations and on-site assembly for large-scale projects. With an optimized free volume of over 97%, the CF-12 ensures maximum efficiency in heat transfer, biological treatment, and water distribution, making it ideal for cooling towers, agricultural applications, wastewater treatment, and complex mass transfer processes.